18 Braiding reels

Process reels for braiding wire

TOLERANCES

All dimensions, weights and loads stated are approximate values; tolerances and deviations which are customary for the industry remain reserved.

Material

POM = polyacetal

ABS = acrylonitrile-butadiene-styrene

PA6 = polyamide

Other materials and colours on request.

Further details regarding material can be found in our material data sheets.

Material Information

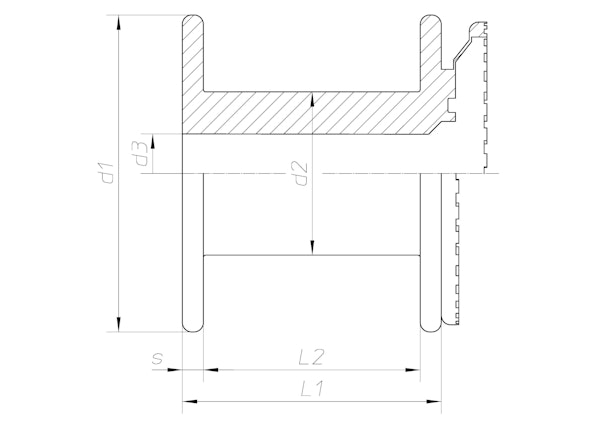

| Designation | Flange Ø | Barrel Ø | Central bore Ø | Width | Winding width | Flange thickness |

Winding- volume |

Central bore Ø tapered part |

Drive- hole/pin |

Drive- distance |

|---|---|---|---|---|---|---|---|---|---|---|

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Reel WA 65/16-80

Reel WA 65/16-80

|

65.8 | 35.3 | 16.8 | 82.2 | 71.2 | 5.5 | 172 | |||

Reel WA 65/16-82 S

Reel WA 65/16-82 S

|

67 | 34.5 | 16.5 | 81.8 | 69.2 | 179 | ||||

Reel WA 65/16-117 S

Reel WA 65/16-117 S

|

67 | 34.5 | 16.5 | 116.6 | 104 | 269 | ||||

Reel SPI 75/10-100 S

Reel SPI 75/10-100 S

|

75 | 23 | 10 | 100 | 70 | 280 | ||||

Reel SPI 80/10-100 S

Reel SPI 80/10-100 S

|

80 | 23 | 10 | 100 | 80 | 368 | ||||

Reel WA 80/16-86 S

Reel WA 80/16-86 S

|

80 | 34.5 | 16.5 | 85 | 70.5 | 288 |

Technical drawing

Spools