08 LM / EM reels

Due to a structured modular principle, our reels with diameters from 315–800 mm allow the greatest possible variety of dimension variants and application possibilities as dispatch or process reels

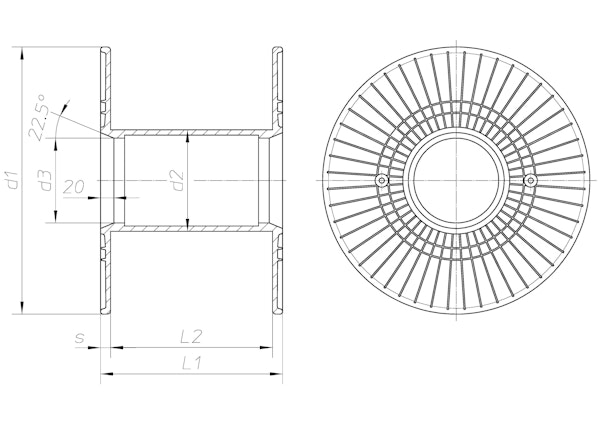

REEL DESIGNATIONS

Reel designations consist of the series description (LM or EM), the flange diameter, and the total outer width of the reels.In addition, it is recommended to specify the barrel diameter (d2) and the winding width.

OUTER WIDTH

The outer width of the reels is normally the winding width (L2) plus 2x the flange thickness (S). If desired, however, in conjunction with smaller central bores hub extensions can also be supplied, which then additionally increase the overall width of the reels.

CENTRAL BORES

The reels have a standard central bore of 127 mm (5 inch) in diameter. Other diameters can also be supplied by means of additional inserts. For various reasons, it has proven to be best to use bore dimensions which are already used in the relevant standards, e.g. 16, 22, 36, 56, 76.4 (3 inch) and 80 mm.

DRIVES

The reels are not fitted with drives as standard. A drive device could engage between the ribs of the flanges, however, this could cause problems with modifications in design and is therefore not recommended. However, reels can also be fitted with plastic or steel pins as drives.

TOLERANCES

All dimensions, weights and loads stated are approximate values; tolerances and deviations which are customary for the industry remain reserved.

Material

Reels in the LM series are made of anthracite coloured impact resistant polystyrene (PS a). Further properties of the material can be found in our material data sheets.

Winding widths

The winding widths given in the table are the most cost-effective. Smaller and larger winding widths can also be supplied. Smaller widths are achieved by shortening the barrel.

Material Information| Designation | Flange Ø | Barrel Ø | Central bore Ø | Width | Winding width | Flange thickness |

Winding- volume |

Central bore Ø tapered part |

Drive- hole/pin |

Drive- distance |

|---|---|---|---|---|---|---|---|---|---|---|

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Reel EM 315/60-240

Reel EM 315/60-240

|

315 | 100 | 60 | 240 | 50 - 217 | 11.5 | 3504 - 15207 | |||

Reel EM 315/127-273

Reel EM 315/127-273

|

315 | 160 | 16 - 127 | 273 | 50 - 250 | 11.5 | 2891 - 14456 | |||

Reel LM 315/60-240

Reel LM 315/60-240

|

315 | 100 | 60 | 240 | 50 - 217 | 11.5 | 3504 - 15207 | |||

Reel LM 315/127-273

Reel LM 315/127-273

|

315 | 160 | 16 - 127 | 273 | 50 - 250 | 11.5 | 2891 - 14456 | 143.5 | ||

Reel EM 350/127-303

Reel EM 350/127-303

|

350 | 180 | 16 - 127 | 303 | 50 - 280 | 11.5 | 3538 - 19814 | 143.5 | ||

Reel EM 350/127-333

Reel EM 350/127-333

|

350 | 224 | 16 - 127 | 333 | 50 - 310 | 11.5 | 2840 - 17609 | 143.5 | ||

Reel LM 350/127-303

Reel LM 350/127-303

|

350 | 180 | 16 - 127 | 303 | 50 - 280 | 11.5 | 3538 - 19814 | 143.5 | ||

Reel LM 350/127-333

Reel LM 350/127-333

|

350 | 224 | 16 - 127 | 333 | 50 - 310 | 11.5 | 2840 - 17609 | 143.5 | ||

Reel EM 400/127-272

Reel EM 400/127-272

|

400 | 152 | 16 - 127 | 272 | 50 - 247 | 12.5 | 5376 - 26557 | 143.5 | ||

Reel EM 400/127-275

Reel EM 400/127-275

|

400 | 160 | 16 - 127 | 275 | 50 - 250 | 12.5 | 5278 - 26389 | 143.5 | ||

Reel EM 400/127-305

Reel EM 400/127-305

|

400 | 180 | 16 - 127 | 305 | 50 - 280 | 12.5 | 5011 - 28061 | 143.5 | ||

Reel EM 400/127-310

Reel EM 400/127-310

|

400 | 200 | 16 - 127 | 310 | 50 - 285 | 12.5 | 4712 - 26861 | 143.5 | ||

Reel EM 400/127-401

Reel EM 400/127-401

|

400 | 144 | 16 - 127 | 425 | 50 - 400 | 12.5 | 5469 - 43751 | 143.5 | ||

Reel LM 400/127-272

Reel LM 400/127-272

|

400 | 152 | 16 - 127 | 272 | 50 - 247 | 12.5 | 5376 - 26557 | 143.5 | ||

Reel LM 400/127-275

Reel LM 400/127-275

|

400 | 160 | 16 - 127 | 275 | 50 - 250 | 12.5 | 5278 - 26389 | 143.5 | ||

Reel LM 400/127-305

Reel LM 400/127-305

|

400 | 180 | 16 - 127 | 305 | 50 - 280 | 12.5 | 5011 - 28061 | 143.5 | ||

Reel LM 400/127-310

Reel LM 400/127-310

|

400 | 200 | 16 - 127 | 310 | 50 - 285 | 12.5 | 4712 - 26861 | 143.5 | ||

Reel LM 400/127-401

Reel LM 400/127-401

|

400 | 144 | 16 - 127 | 425 | 50 - 400 | 12.5 | 5469 - 43751 | 143.5 | ||

Reel EM 450/127-305

Reel EM 450/127-305

|

450 | 180 | 16 - 127 | 305 | 50 - 280 | 12.5 | 6680 - 37407 | 143.5 | ||

Reel EM 450/127-310

Reel EM 450/127-310

|

450 | 200 | 16 - 127 | 310 | 50 - 285 | 12.5 | 6381 - 36374 | 143.5 | ||

Reel EM 450/127-335

Reel EM 450/127-335

|

450 | 224 | 16 - 127 | 335 | 50 - 310 | 12.5 | 5982 - 37087 | 143.5 | ||

Reel LM 450/127-305

Reel LM 450/127-305

|

450 | 180 | 16 - 127 | 305 | 50 - 280 | 12.5 | 6680 - 37407 | 143.5 | ||

Reel LM 450/127-310

Reel LM 450/127-310

|

450 | 200 | 16 - 127 | 310 | 50 - 285 | 12.5 | 6381 - 36374 | 143.5 | ||

Reel LM 450/127-335

Reel LM 450/127-335

|

450 | 224 | 16 - 127 | 335 | 50 - 310 | 12.5 | 5982 - 37087 | 143.5 | ||

Reel LM 540/33,5-275

Reel LM 540/33,5-275

|

540 | 315 | 33.5 | 275 | 50 - 425 | 20 | 7554 - 64213 | 2x35+2x25 | 115 | |

Reel EM 630/127-420

Reel EM 630/127-420

|

630 | 315 | 16 - 127 | 420 | 50 - 425 | 20 | 11690 - 99362 | 143.5 | ||

Reel LM 630/127-420

Reel LM 630/127-420

|

630 | 315 | 16 - 127 | 420 | 50 - 425 | 20 | 11690 - 99362 | 143.5 |

Technical drawing

Spools