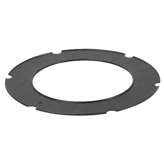

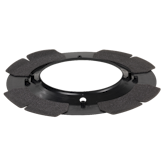

20 Pressure rings

Pressure rings for the reliable processing of welding wire from drums They serve as pay-off discs in winding drums and thus prevent the upper coils in the wire container from slipping or forming loops

USE

Pressure rings protect the wire in winding drums during transport by pressing down on the coil thus preventing slippage of the upper coils in the wire container.

When unwinding from the container, the pressure ring guides the wire and prevents looping.

VERPACKUNGEN

On request

TOLERANCES

All dimensions, weights and loads stated are approximate values; tolerances and deviations which are customary for the industry remain reserved.

Material

PP TSG = polypropylene structural foam

HIPS = high impact polystyrene

Further details regarding material can be found in our material data sheets.

Material Information

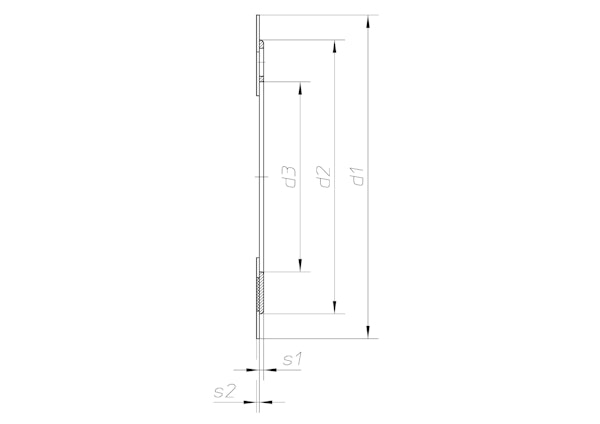

| Designation | Flange Ø | Barrel Ø | Central bore Ø | Width | Winding width | Flange thickness |

Winding- volume |

Central bore Ø tapered part |

Drive- hole/pin |

Drive- distance |

|---|---|---|---|---|---|---|---|---|---|---|

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Tension ring 530/340

Tension ring 530/340

|

530 | 530 | 340 | 7 | ||||||

Tension ring TR 490/334

Tension ring TR 490/334

|

554 | 490 | 334 | 35 | 2 | |||||

Tension ring 490/340

Tension ring 490/340

|

580 | 490 | 340 | 12.7 | 7.7 | |||||

Tension ring TR 570/334

Tension ring TR 570/334

|

630 | 570 | 334 | 35 | 2 | |||||

Tension ring 570/380

Tension ring 570/380

|

660 | 570 | 380 | 10.4 | 5.4 | |||||

Tension ring TR 615/334

Tension ring TR 615/334

|

675 | 615 | 334 | 35 | 2 | |||||

Tension ring TR 645/334

Tension ring TR 645/334

|

705 | 645 | 334 | 35 | 2 |

Technical drawing

Spools