19 Reels and reel containers

Our containers protect the reels and winding material during transport and are also used during unwinding

Our containers protect the reels and winding material during transport.

In addition, they serve as an unwinding device (over end pay-off at high speeds) and are therefore supplied with an absolutely smooth inner surface. All containers have a window so that the fill level of the reel can be checked even during unwinding without lifting the cover. The pay-off opening has a fixed hinged cover. We recommend the use of appropriate load handling equipment for lifting and transport in the centre bore.In case of using the “rope” for lifting and handling, all components of the “system container” need to be checked for damage. The container is closed with a clamping ring which can also be sealed. The reel/container combination protects the reel and can be used repeatedly which means this method of shipping wire is quickly amortized. The available material qualities are shown in the table below.

IMPORTANT

Shrink-wrapped pallets of packages must not be stored in direct sunlight, as the heat build-up may cause the plastic to warp permanently. Shrink-wrapped pallets are the preferred mode of shipment for containers and reels alone or containers with reels. Smaller quantities of reels or containers or combinations of these are packed in sturdy corrugated cardboard boxes. On request, we also ship cardboard boxes on shrink-wrapped pallets. Overseas container shipping (20 feet or 40 feet) is also possible. Please ask for shipping quantities.

TOLERANCES

All dimensions, weights and loads stated are approximate values; tolerances and deviations which are customary for the industry remain reserved.

Material

HIPS = high impact polystyrene

ABS = acrylonitrile-butadiene-styrene

PA6 = polyamide

If there is a risk of the reels coming into contact with aromatic hydrocarbons (solvents) or being used at very low temperatures, we recommend the use of at least ABS or PA6. More detailed information on this can be found in our material data sheets.

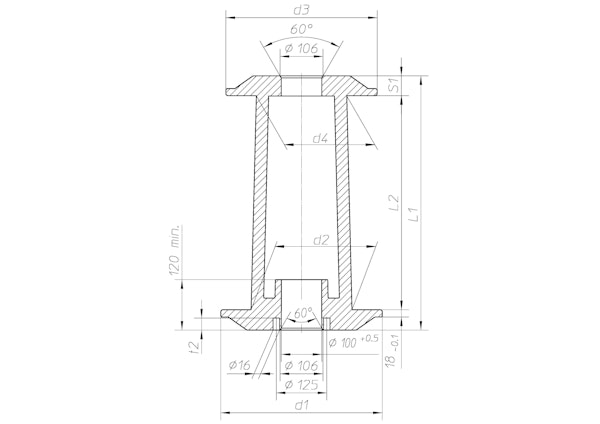

| Designation | Flange Ø | Barrel Ø | Central bore Ø | Width | Winding width | Flange thickness |

Winding- volume |

Central bore Ø tapered part |

Drive- hole/pin |

Drive- distance |

|---|---|---|---|---|---|---|---|---|---|---|

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Reel 250 E

Reel 250 E

|

250 | 160 | 16 - 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel 250/36 E

Reel 250/36 E

|

250 | 160 | 30 - 36 | 200 | 160 | 20 | 4637 | |||

Reel 250/400 E

Reel 250/400 E

|

250 | 140 | 30.6 - 100 | 400 | 335 | 32.5 | 9709 | 106 | 2 x 16 | 62.5 |

Reel DWF 250

Reel DWF 250

|

250 | 160 | 16 - 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel EPA 250-E

Reel EPA 250-E

|

250 | 160 | 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel EPA 250/36-E

Reel EPA 250/36-E

|

250 | 160 | 36 | 200 | 160 | 20 | 4637 | |||

Reel G 250

Reel G 250

|

250 | 160 | 16 - 22 | 198 | 158 | 20 | 4637 | 34 | 2x13 | 32 |

Reel GL 250/400

Reel GL 250/400

|

250 | 140 | 30.6 - 100 | 400 | 335 | 32.5 | 9709 | |||

Reel HKV 250 one piece

Reel HKV 250 one piece

|

250 | 140 | 16 - 22 | 250 | 133 | 58.5 | 6469 | 34 | 2x13 | 32 |

Reel K 250

Reel K 250

|

250 | 160 | 16 - 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel K 250/22 with radius

Reel K 250/22 with radius

|

250 | 160 | 16 - 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel K 250/36 with radius

Reel K 250/36 with radius

|

250 | 160 | 30 - 36 | 200 | 160 | 20 | 4637 | |||

Reel KK 250 KON

Reel KK 250 KON

|

250 | 150 | 16 - 22 | 200 | 160 | 20 | 4834 | 34 | 2x13 | 32 |

Reel 258/322

Reel 258/322

|

258 | 160 | 30.5 - 100 | 322 | 280 | 21 | 6728 | |||

Reel 315/500-E

Reel 315/500-E

|

315 | 180 | 100 | 500 | 425 | 37.5 | 19768 | 106 | 16 x 2 | 62.5 |

Reel 400/630 E

Reel 400/630 E

|

400 | 224 | 100 | 630 | 530 | 50 | 40585 | 106 | 2x16 | 62.5 |

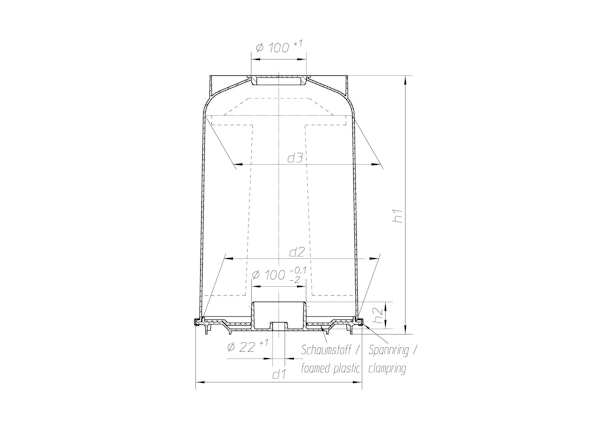

| Designation | Outer Ø | Overall height | Inner Ø bottom | Inner Ø top | |

|---|---|---|---|---|---|

| d1 max | h1 max | d2 | d3 | h2 min | |

Container VB 250/36

Container VB 250/36

|

304 | 273 | - | - | - |

Container VB 250/250

Container VB 250/250

|

304 | 345 | - | - | - |

Container VB 250/400

Container VB 250/400

|

315 | 500 | 270 | 280 | 50 |

Container VB 315/500

Container VB 315/500

|

400 | 630 | 338 | 355 | 63 |

Container VB 400/630

Container VB 400/630

|

500 | 800 | 428 | 450 | 80 |

Technical drawing

Spools

Container