02 Spools with conical flanges

Enable high pay-off speeds and easy gliding of the wire. The conical shape of the flange allows clean and stable winding even with tape profiles, as well as reliable unwinding

APPLICATIONS

The non-rectangular flange allows the wire to glide easily, even when the reel is almost empty.

This is particularly advantageous when operation is interrupted at high pay-off speeds.

The rim of the HKV reels features a rounded “hump” (Couvergin-Buckel) which further reduces contact between the wire to be paid off and the flange surface, allowing the wire to glide even better.

IMPORTANT

If pallet packaging is indicated, this is the preferred method of packing the reels.

Please note that the pallets must not be stored in direct sunlight, as the heat build-up may cause the plastic to warp permanently.

DESIGN

The reels with two conical flanges have been intentionally designed this way.

The pressure build-up on the inner surfaces of the flange is better absorbed with this design than with the previously used reels with a flange at right angles to the barrel.

TOLERANCES

All dimensions, weights and loads stated are approximate values; tolerances and deviations which are customary for the industry remain reserved.

The material options for the reels are indicated as follows: HIPS = high impact polystyrene ABS = acrylonitrile-butadiene-styrene PA6 = glass fibre reinforced polyamide

HIPS = high impact polystyrene

ABS = acrylonitrile-butadiene-styrene

PA6 = glass fibre reinforced polyamide

Further details and the available colours can be found in our material data sheets.The standard colour for HIPS is green.

For PA6 and ABS it is anthracite.

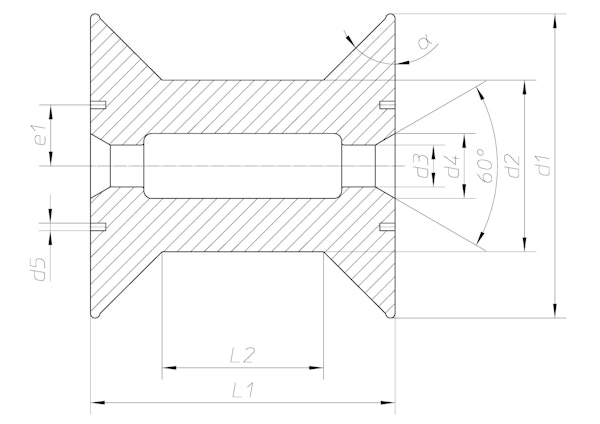

| Designation | Flange Ø | Barrel Ø | Central bore Ø | Width | Winding width | Flange thickness |

Winding- volume |

Central bore Ø tapered part |

Drive- hole/pin |

Drive- distance |

|---|---|---|---|---|---|---|---|---|---|---|

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Reel HKL 40

Reel HKL 40

|

40 | 25 | 8 | 90 | 70 | 10 | 58 | 15 | ||

Reel HK 76/45

Reel HK 76/45

|

63.5 | 44.4 | 8 - 16 | 86.3 | 60 | 13 | 113 | |||

Reel HKK 76

Reel HKK 76

|

63 | 43.5 | 16 | 60 | 34 | 13 | 72 | |||

Reel K 63

Reel K 63

|

63 | 40 | 11 | 63 | 49 | 7 | 91 | 15 | 1x5 | 14 |

Reel HK 80 S

Reel HK 80 S

|

80 | 55 | 8 - 16 | 100 | 69.5 | 15 | 220 | |||

Reel HK 80/16-95

Reel HK 80/16-95

|

80 | 38 | 16 | 95 | 77 | 9 | 321 | |||

Reel HK 80/45

Reel HK 80/45

|

80 | 55 | 8 - 16 | 100 | 69.5 | 15 | 220 | |||

Reel HK 100/59-160

Reel HK 100/59-160

|

100 | 75 | 59 | 160 | 91 | 34.5 | 429 | |||

Reel HKV 100

Reel HKV 100

|

100 | 56 | 16 | 100 | 49 | 25.5 | 390 | 19.5 | ||

Reel HKL 125

Reel HKL 125

|

125 | 71 | 16 - 22 | 200 | 140 | 30 | 1407 | 34 | 2x7 | 20 |

Reel HKL 125/22-300

Reel HKL 125/22-300

|

125 | 71 | 16 - 22 | 300 | 240 | 30 | 2238 | 34 | 2x7 | 20 |

Reel HKV 125

Reel HKV 125

|

125 | 71 | 16 | 125 | 65 | 30 | 767 | 24 | 2x7 | 20 |

Reel HK 130/82-176

Reel HK 130/82-176

|

130 | 100 | 82 | 176 | 92 | 42 | 743 | |||

Reel 130/30°-105 **

Reel 130/30°-105 **

|

160 | 82 | 76.6 | 105 | 53 | 24.5 | 1080 | |||

Reel HKV 160

Reel HKV 160

|

160 | 90 | 16 - 22 | 160 | 85 | 37.5 | 1675 | 34 | 2x13 | 32 |

Reel HKV 200

Reel HKV 200

|

200 | 112 | 16 - 22 | 200 | 106 | 47 | 3271 | 34 | 2x13 | 32 |

Reel HK 250/45 SP

Reel HK 250/45 SP

|

250 | 160 | 22 - 127 | 200 | 91 | 53 | 4120 | |||

Reel HKV 250 one piece

Reel HKV 250 one piece

|

250 | 140 | 16 - 22 | 250 | 133 | 58.5 | 6469 | 34 | 2x13 | 32 |

Reel FLP 300/36-310

Reel FLP 300/36-310

|

300 | 112 | 36 | 310 | 125 | 92.5 | 15400 | |||

Reel FLP 300/100-310

Reel FLP 300/100-310

|

300 | 112 | 36 - 100 | 310 | 125 | 92.5 | 15400 | 2x15 | 65.5 | |

Reel FLP 335/36-314

Reel FLP 335/36-314

|

335 | 140 | 36 | 314 | 82 | 116 | 17056 |

Technical drawing

Spools