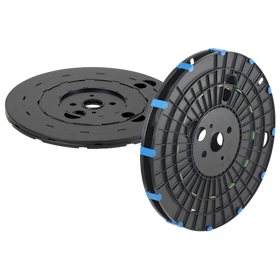

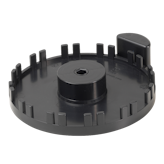

01 Tape reels

Suitable for lighter winding materials such as stamped parts and collated components. Simple assembly and disassembly

FASTENERS

To provide the winding material with additional protection, it is possible to attach spacer clamps (available for up to 110 mm winding width) to the circumference of the flange.

DELIVERY

Flanges and barrels are delivered separately. Flanges are delivered on pallets or in cardboard boxes. Separate storage of the flanges on a flat base prevents warping even during long storage.

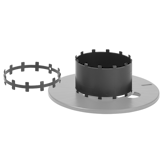

ASSEMBLY

The barrels have lugs on both sides which lock into corresponding slots.

DISASSEMBLY

The reels can be disassembled at any time with an auxiliary device. This can save up to 75% volume during transport.

IMPORTANT

Shrink-wrapped pallets of packages must not be stored in direct sunlight, as the heat build-up may cause the plastic to warp permanently.

START HOLE/ACCESS OPENING/FILL LEVEL INDICATOR

The barrels have an axial slot (5.5 mm wide) which extends over the entire width. The flanges have access openings in line with the slot. The flanges have helically arranged slotted holes, which indicate the respective fill level of the reels.

LABEL AREA

All flanges have several label areas up to a size of 60 x 80 mm. Some flanges feature label pockets.

MARKING

For an additional charge, flanges can also be supplied with your company name, in colour if required.

TOLERANCES

All dimensions, weights and loads stated are approximate values; tolerances and deviations which are customary for the industry remain reserved.

Application

These reels are particularly suitable for lighter winding materials (depending on the application up to approx. 12 kg, in some cases also far more), e.g. stamped parts, collated components, etc. Problem-free storage even with different widths as well as simple assembly/disassembly are the outstanding features of this system.

Material + Colours

Flanges and barrels are made of impact-resistant polystyrene. The standard colour is black/anthracite.

Other colours are available for barrel and flange at an additional charge.

| Designation | Flange Ø | Barrel Ø | Central bore Ø | Width | Winding width | Flange thickness |

Winding- volume |

Central bore Ø tapered part |

Drive- hole/pin |

Drive- distance |

|---|---|---|---|---|---|---|---|---|---|---|

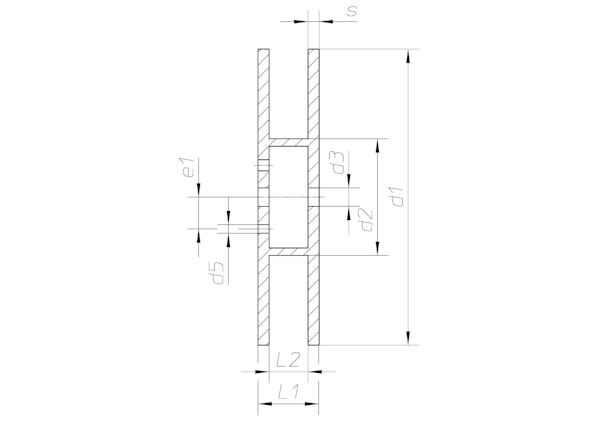

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Flange BSH 315

Flange BSH 315

|

315 | 160 | 20 - 56 | 8.5 - 380 | 12 | 492 - 21973 | 2x20+2x13 | 56 | ||

Flange BSH 450

Flange BSH 450

|

450 | 160 | 20 - 56 | 8.5 - 380 | 12 | 1181 - 52796 | 2x20+2x13 | 56 | ||

Flange BSH 500

Flange BSH 500

|

500 | 160 | 20 - 56 | 8.5 - 380 | 12 | 1498 - 66972 | 2x20+2x13 | 56 | ||

Flange BSL 500

Flange BSL 500

|

500 | 315 | 20 - 56 | 8.5 - 380 | 12 | 1007 - 44999 | 2x20+2x13 | 56 | ||

Flange BSH 590

Flange BSH 590

|

590 | 160 | 20 - 56 | 8.5 - 380 | 12 | 2153 - 96251 | 2x20+2x13 | 56 | ||

Flange BSH 630

Flange BSH 630

|

630 | 160 | 20 - 76 | 8.5 - 380 | 12 | 2479 - 110815 | 2x20+2x13 | 56 | ||

Flange BSHS 630/22,4

Flange BSHS 630/22,4

|

630 | 160 | 22.4 | 8.5 - 380 | 9 | 2479 - 110815 | 2x20+2x13 | 56 | ||

Flange BSL 630

Flange BSL 630

|

630 | 315 | 20 - 56 | 8.5 - 380 | 12 | 1987 - 88841 | 2x20+2x13 | 56 | ||

Flange BSL 640

Flange BSL 640

|

640 | 315 | 20 - 56 | 8.5 - 380 | 12 | 2072 - 92632 | 2x20+2x13 | 56 | ||

Flange BSL-HD 800

Flange BSL-HD 800

|

800 | 315 | 20 - 56 | 8.5 - 380 | 20 | 3610 - 161395 | 2x20+2x13 | 56 | ||

Flange BSL 800

Flange BSL 800

|

800 | 315 | 20 - 56 | 8.5 - 380 | 15 | 3610 - 161395 | 2x20+2x13 | 56 | ||

Flange BSM-HD 800

Flange BSM-HD 800

|

800 | 400 | 20 - 56 | 10 - 160 | 20 | 3770 - 60319 | 2x20+2x13 | 56 | ||

Flange BSM 800

Flange BSM 800

|

800 | 400 | 20 - 56 | 10 - 160 | 15 | 3770 - 60319 | 2x20+2x13 | 56 | ||

Flange BSO-HD 800

Flange BSO-HD 800

|

800 | 600 | 20 - 56 | 10 - 160 | 20 | 2199 - 35186 | 2x20+2x13 | 56 | ||

Flange BSO 800

Flange BSO 800

|

800 | 600 | 20 - 56 | 10 - 160 | 15 | 2199 - 35186 | 2x20+2x13 | 56 | ||

Flange BSM 1000

Flange BSM 1000

|

1000 | 400 | 20 - 56 | 10 - 160 | 15 | 6597 - 105558 | 2x20+2x13 | 56 | ||

Flange BSO 1000

Flange BSO 1000

|

1000 | 600 | 20 - 56 | 10 - 160 | 15 | 5027 - 80425 | 2x20+2x13 | 56 | ||

Barrel BSH 160/8,5-110

Barrel BSH 160/8,5-110

|

160 | 8.5 - 110 | ||||||||

Barrel BSH 160/110-380

Barrel BSH 160/110-380

|

160 | 110 - 380 | ||||||||

Barrel BSL 315/8,5-380

Barrel BSL 315/8,5-380

|

315 | 8.5 - 380 | ||||||||

Barrel BSM 400/10-160

Barrel BSM 400/10-160

|

400 | 10 - 160 | ||||||||

Barrel BSO 600/10-160

Barrel BSO 600/10-160

|

600 | 10 - 160 | ||||||||

Dismanling BSH

Dismanling BSH

|

160 | |||||||||

Dismanling BSL

Dismanling BSL

|

315 |

Technical drawing

Spools