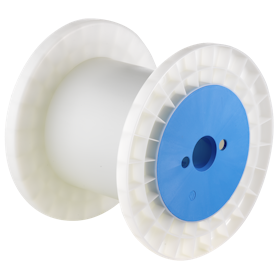

04 Cylindrically barrelled delivery spools

Reels adapted for specialized applications with additional chemical (such as ESC) or mechanical stresses

DIFFERENCES

The reels listed in this table differ from those according to DIN EN 60264-2-2 (DIN 46399) mostly only in the design and dimension of the bore or in the weight based on different designs. The EPA spool series is particularly suitable for use as disposable reels for wires coated with oils, greases, lubricants, etc., such as woven wires or monofilaments. The K spool series with core/flange transitional radius also offers good strength properties.

IMPORTANT

Shrink-wrapped pallets of packages must not be stored in direct sunlight, as the heat build-up may cause the plastic to warp permanently. Shrink-wrapped pallets are the preferred mode of shipment for reels with diameters ranging from 125–500 mm. All types can also be packed in sturdy corrugated cardboard boxes. On request, we also ship cardboard boxes on shrink-wrapped pallets.

SPECIAL REQUESTS

Other bore diameters are available on request, and other insertion cones can also be fitted. Please contact us if you cannot find the reel you require.

TOLERANCES

All dimensions, weights and loads stated are approximate values; tolerances and deviations which are customary for the industry remain reserved.

Material

The material options for the reels are indicated as follows:

HIPS = high impact polystyrene

ABS = acrylonitrile-butadiene-styrene

PA6 = polyamide

TSG = structural foam

Further details and the available colours can be found in our material data sheets. The standard colour for HIPS is green. For PA6 and ABS it is anthracite. Further materials on request.

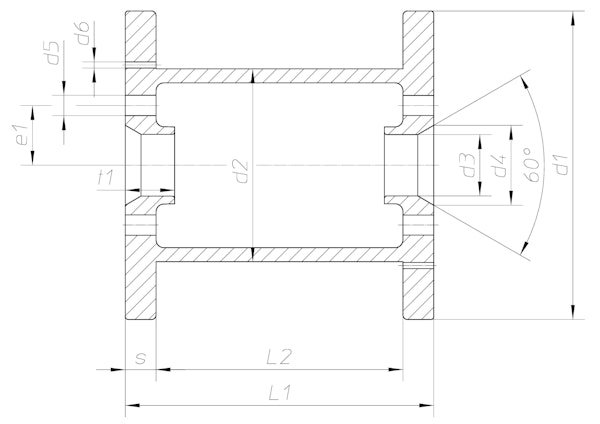

| Designation | Flange Ø | Barrel Ø | Central bore Ø | Width | Winding width | Flange thickness |

Winding- volume |

Central bore Ø tapered part |

Drive- hole/pin |

Drive- distance |

|---|---|---|---|---|---|---|---|---|---|---|

| d1 [mm] | d2 [mm] | d3 [mm] | L1 [mm] | L2 [mm] | S [mm] | V [cm³] | d4 [mm] | d5 [mm] | E1 [mm] | |

Reel SPI 80/10-100 S

Reel SPI 80/10-100 S

|

80 | 23 | 10 | 100 | 80 | 368 | ||||

Reel EPA 100-E

Reel EPA 100-E

|

100 | 63 | 16 | 100 | 80 | 10 | 379 | 24 | 2x7 | 20 |

Reel EPA 125-E

Reel EPA 125-E

|

125 | 80 | 16 | 125 | 100 | 12.5 | 725 | 24 | 2x7 | 20 |

Reel K 125/36

Reel K 125/36

|

125 | 80 | 36 | 125 | 100 | 12.5 | 725 | 2x7 | 20 | |

Reel EPA 160-E

Reel EPA 160-E

|

160 | 100 | 22 | 160 | 128 | 16 | 1568 | 34 | 2x13 | 32 |

Reel K 160/72

Reel K 160/72

|

160 | 100 | 72 | 160 | 128 | 16 | 1568 | |||

Reel EPA 200-E

Reel EPA 200-E

|

200 | 125 | 22 | 200 | 160 | 20 | 3063 | 34 | 2x13 | 32 |

Reel K 200/22 with radius

Reel K 200/22 with radius

|

200 | 125 | 16 - 22 | 200 | 160 | 20 | 3063 | 34 | 2x13 | 32 |

Reel K 200/36

Reel K 200/36

|

200 | 125 | 36 | 200 | 160 | 20 | 3063 | |||

Reel K 200/36 with radius

Reel K 200/36 with radius

|

200 | 125 | 36 | 200 | 160 | 20 | 3063 | |||

Reel MK 200

Reel MK 200

|

200 | 125 | 22 | 200 | 160 | 20 | 3063 | 34 | 2x13 | 32 |

Reel MK 200-R

Reel MK 200-R

|

200 | 125 | 22 | 200 | 160 | 20 | 3063 | 34 | 2x13 | 32 |

Reel MK 200-R HD

Reel MK 200-R HD

|

200 | 125 | 22 | 200 | 160 | 20 | 3063 | 34 | 2x13 | 32 |

Reel R 200-E

Reel R 200-E

|

200 | 100 | 22 | 200 | 160 | 20 | 3769 | 34 | 2x13 | 32 |

Reel SP 200/100

Reel SP 200/100

|

200 | 125 | 100 | 200 | 160 | 20 | 3063 | |||

Reel DWF 250/36

Reel DWF 250/36

|

250 | 160 | 30 - 36 | 200 | 160 | 20 | 4637 | |||

Reel DWF 250/75 K

Reel DWF 250/75 K

|

250 | 160 | 75 | 200 | 160 | 20 | 4637 | |||

Reel DWF 250/76 K

Reel DWF 250/76 K

|

250 | 160 | 76 | 200 | 160 | 20 | 4637 | |||

| Reel DWF 250/102 | 250 | 160 | 102 | 200 | 160 | 20 | 4637 | |||

Reel DWF 250/127

Reel DWF 250/127

|

250 | 160 | 127 | 200 | 160 | 20 | 4637 | |||

Reel DWF 250/150,7

Reel DWF 250/150,7

|

250 | 160 | 150.7 | 200 | 160 | 20 | 4637 | |||

Reel EPA 250-E

Reel EPA 250-E

|

250 | 160 | 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel EPA 250/36-E

Reel EPA 250/36-E

|

250 | 160 | 36 | 200 | 160 | 20 | 4637 | |||

Reel G 250

Reel G 250

|

250 | 160 | 16 - 22 | 198 | 158 | 20 | 4637 | 34 | 2x13 | 32 |

Reel K 250-R

Reel K 250-R

|

250 | 128 | 22.2 | 200 | 160 | 20 | 5795 | |||

Reel K 250/22 with radius

Reel K 250/22 with radius

|

250 | 160 | 16 - 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel K 250/31,75

Reel K 250/31,75

|

250 | 160 | 31.8 | 200 | 160 | 20 | 4637 | |||

Reel K 250/36

Reel K 250/36

|

250 | 160 | 30 - 36 | 200 | 160 | 20 | 4637 | |||

Reel K 250/36 with radius

Reel K 250/36 with radius

|

250 | 160 | 30 - 36 | 200 | 160 | 20 | 4637 | |||

Reel K 250/102

Reel K 250/102

|

250 | 160 | 102 | 200 | 160 | 20 | 4637 | |||

Reel K 250/102 with radius

Reel K 250/102 with radius

|

250 | 160 | 102 | 200 | 160 | 20 | 4637 | |||

Reel K 250/127

Reel K 250/127

|

250 | 160 | 127 | 200 | 160 | 20 | 4637 | |||

Reel K 250/127 with radius

Reel K 250/127 with radius

|

250 | 160 | 127 | 200 | 160 | 20 | 4637 | |||

Reel K 250/152,2

Reel K 250/152,2

|

250 | 160 | 152.2 | 200 | 160 | 20 | 4637 | |||

Reel KK 250 KON

Reel KK 250 KON

|

250 | 150 | 16 - 22 | 200 | 160 | 20 | 4834 | 34 | 2x13 | 32 |

Reel MK 250-R

Reel MK 250-R

|

250 | 160 | 22 | 200 | 160 | 20 | 4637 | 34 | 2x13 | 32 |

Reel SP 250/36

Reel SP 250/36

|

250 | 160 | 36 | 200 | 160 | 20 | 4637 | |||

Reel SP 250/102

Reel SP 250/102

|

250 | 160 | 102 | 200 | 160 | 20 | 4637 | |||

Reel SP 250/127 K

Reel SP 250/127 K

|

250 | 160 | 127 | 200 | 160 | 20 | 4637 | |||

Reel SP 250/127 Z

Reel SP 250/127 Z

|

250 | 160 | 127 | 200 | 160 | 20 | 4637 | |||

Reel DWF 355/102

Reel DWF 355/102

|

355 | 224 | 102 | 200 | 160 | 20 | 9531 | |||

Reel K 355/36 with radius

Reel K 355/36 with radius

|

355 | 224 | 36 | 200 | 160 | 20 | 9531 | 60 | 2 x 26 | 80 |

Reel DWF 500/36-350

Reel DWF 500/36-350

|

500 | 315 | 36 | 350 | 280 | 35 | 33157 | 60 | 2 x 26 | 80 |

Reel DWF 500/127-250

Reel DWF 500/127-250

|

500 | 315 | 127 | 250 | 180 | 35 | 21315 | 2 x 26 | 80 | |

Reel DWF 500/127-350

Reel DWF 500/127-350

|

500 | 315 | 127 | 350 | 280 | 35 | 33157 | 2 x 26 | 80 |

Technical drawing

Spools